TANK KLEEN specializes in maintaining and recovering petroleum products along with the tanks they are stored in. We use specially engineered equipment, additives and testing techniques to ensure your fuel supply is reliable. All of our systems use multi-stage filtration and a water coalescing process to help recover a quality product with little waste. Our systems are built in house to match the demands our clients require.

TANK KLEEN specializes in maintaining and recovering petroleum products along with the tanks they are stored in. We use specially engineered equipment, additives and testing techniques to ensure your fuel supply is reliable. All of our systems use multi-stage filtration and a water coalescing process to help recover a quality product with little waste. Our systems are built in house to match the demands our clients require.

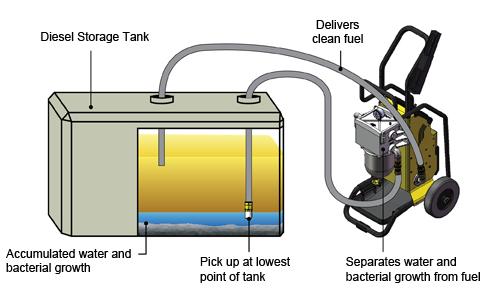

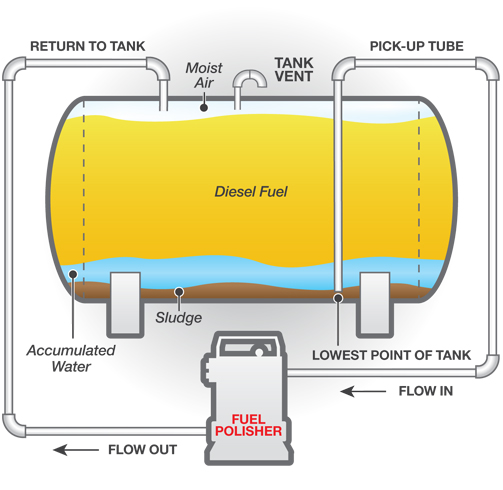

A Quick Summary Of How The Fuel Polishing Process Works.

A sample is taken from the tank, showing our TANK KLEEN technician what will be required to properly recover the product. A “cross section” will show the layers of fuel, water and algae contamination. The first step is to remove all heavy solids and waste water that has accumulated at the bottom of the tank. The remaining fuel is then extracted from the tank, ran through a series of tight, low micron bag filters, then into a water separation housing. Free water and moisture is coalesced into a collection vessel and later disposed. Our water separator cartridge filter removes any additional moisture before the fuel is returned to the tank. This process repeats itself until the fuel is free of all contaminates including algae, water, rust and sediment.

A sample is taken from the tank, showing our TANK KLEEN technician what will be required to properly recover the product. A “cross section” will show the layers of fuel, water and algae contamination. The first step is to remove all heavy solids and waste water that has accumulated at the bottom of the tank. The remaining fuel is then extracted from the tank, ran through a series of tight, low micron bag filters, then into a water separation housing. Free water and moisture is coalesced into a collection vessel and later disposed. Our water separator cartridge filter removes any additional moisture before the fuel is returned to the tank. This process repeats itself until the fuel is free of all contaminates including algae, water, rust and sediment.

One optional step in the process is Fuel Additive Introduction. As the fuel is circulated we inject a proprietary blend of biocides, conditioners and stabilizers to protect your valuable commodity while adding to its shelf life.

Ask us about our Complete Fuel Management Program, which takes the worry out of your fuel supply. We can setup monthly testing, manage your fuel supply and offer services all under one package.

How our services improve your business

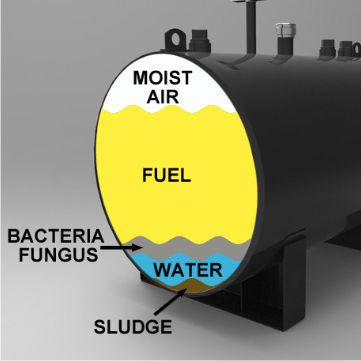

For most of our clients, fuel is an integral part of their daily business. Whether it is fleet fuel, construction equipment “go-juice” or power for their backup generators, an unstable fuel supply can be extremely costly, or in some situations be a matter of life and death. Most petroleum products only have a 90 day shelf life before they begin to change form. From phase-separation to algae growth, there are many issues that can arise which can compromise your stored fuel. The fuel we use has been modified from its original state and turned into a combustible product. These products have been engineered to lower emissions, lubricate engine components and create power. Over time some of the changes that were made to the products start to fail. For example, in the last decade we have introduced Ethanol to our unleaded gasoline products in an effort to create a cleaner burning fuel. While it does have its benefits, stored ethanol will naturally begin to separate, creating moisture as a byproduct. Diesel fuels also have their down falls. Being an organic substance along with being exposed to temperature change, moisture content will indefinitely cause algae growth and the formation of engine damaging particulates. This particulates will eventually turn into a thick sludge, ultimately ruining your costly fuel supply. Moisture in any fuel tank will also cause rust formation and scaling, both which can reap havoc on your equipment.

For most of our clients, fuel is an integral part of their daily business. Whether it is fleet fuel, construction equipment “go-juice” or power for their backup generators, an unstable fuel supply can be extremely costly, or in some situations be a matter of life and death. Most petroleum products only have a 90 day shelf life before they begin to change form. From phase-separation to algae growth, there are many issues that can arise which can compromise your stored fuel. The fuel we use has been modified from its original state and turned into a combustible product. These products have been engineered to lower emissions, lubricate engine components and create power. Over time some of the changes that were made to the products start to fail. For example, in the last decade we have introduced Ethanol to our unleaded gasoline products in an effort to create a cleaner burning fuel. While it does have its benefits, stored ethanol will naturally begin to separate, creating moisture as a byproduct. Diesel fuels also have their down falls. Being an organic substance along with being exposed to temperature change, moisture content will indefinitely cause algae growth and the formation of engine damaging particulates. This particulates will eventually turn into a thick sludge, ultimately ruining your costly fuel supply. Moisture in any fuel tank will also cause rust formation and scaling, both which can reap havoc on your equipment.

Our goal at TANK KLEEN is to manage your fuel COMPLETELY from the source until it is burned. We offer supply agreements, fuel polishing and tank cleaning service programs that give your company peace of mind.